Innovation

By combining our European production with innovative courage and the latest technologies, we help organisations to excel. We develop replacement parts that maximise production and optimise uptime.

By combining our European production with innovative courage and the latest technologies, we help organisations to excel. We develop replacement parts that maximise production and optimise uptime.

Together with our dedicated team, we are a supplier offering solid services and tailor-made solutions to deliver successful customer experiences and build long-term partnerships.

Our communication is of an expert level worldwide, with which we inform and advise our clients. By sharing knowledge and our transparent communication, we offer security.

With our operational perfection, we quickly deliver first-class quality worldwide at the best price. By combining our craftsmanship with modern technology we offer customer specific series.

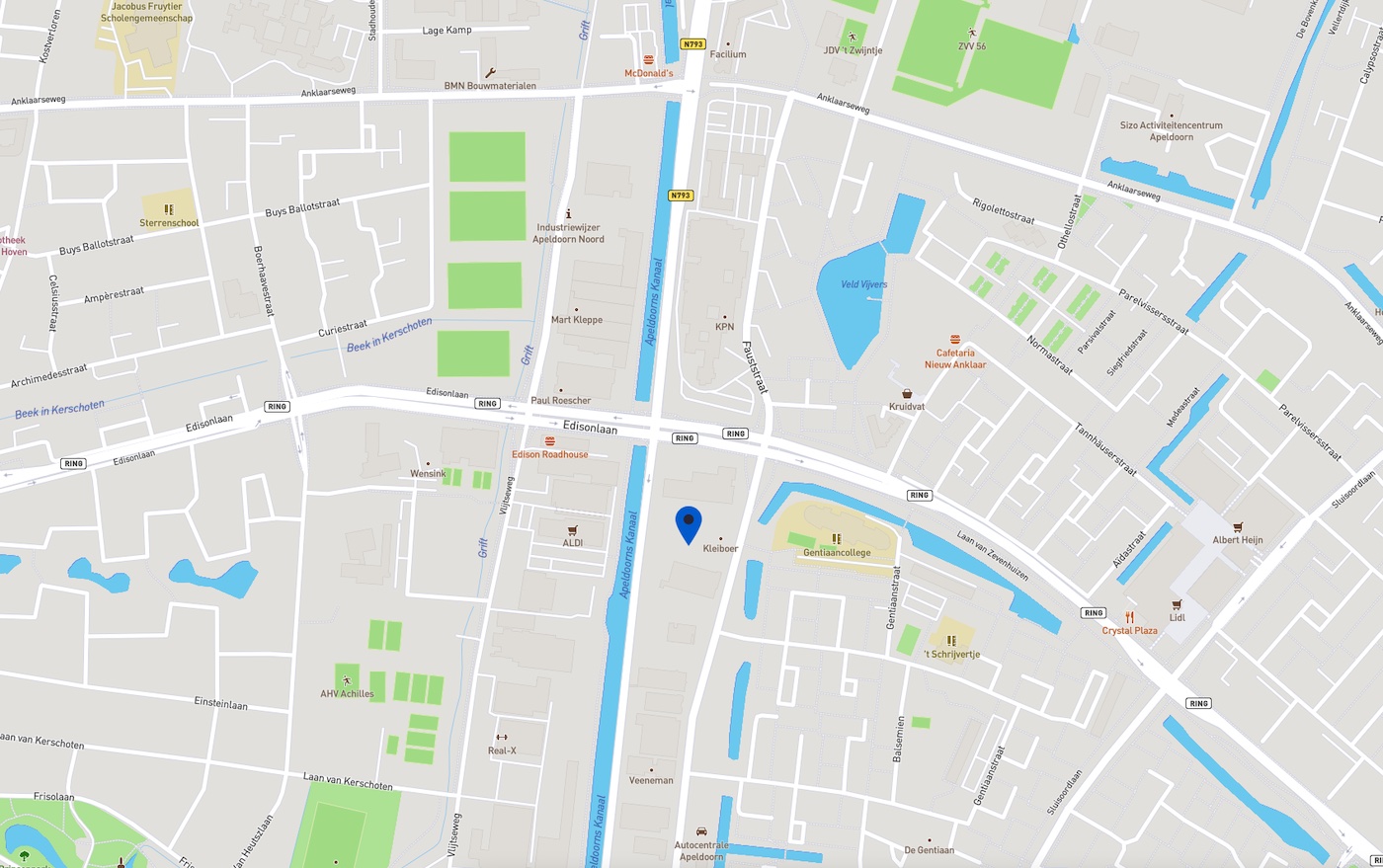

Unlimited Spare Parts (USP) is specialised in designing, producing and grinding of industrial knives and other spare parts for machines in the food and packaging industry. The headquarter and new grinding facility are located in Apeldoorn and we have our own state-of-the-art production facilities in Kielce and Heerhugowaard.

We serve machine manufacturers, end users and maintenance and repair companies (MRO) and have a global customer base with a strong presence in the Benelux, Germany, Poland and France. Our machine parts are used in the meat, confectionery, coffee, pet food, fish, meat substitutes, frozen food, ready meals and fruit and vegetable industries.

More about us